LONGITUDE REBORN

In 2015, Zero West introduced its first timepiece, the L1 Longitude – a modern nod to John Harrison’s H4 clock and the Prime Meridian, also known as Zero Degrees West.

Limited to 20 pieces, it soon earned grail status and set our course through time. Ten years on, the new L3 evolves that story, contemporary, composed, and limited to 50 pieces.

TIME TRAVEL

In the early 18th century, failure to fix longitude at sea led to tragedy – most notably the 1707 Scilly disaster that claimed over 1,400 lives. The Longitude Act followed, and John Harrison’s H4 – seconds-accurate after an 81-day trial – revolutionised navigation. The L3 Longitude honours that breakthrough and Zero West’s British engineering. In 1884, the world chose Greenwich, fixing the Prime Meridian at 51.48°N, 0.00°W—Zero Degrees West—the line that starts every map and clock.

THE MERIDIAN REVEAL

Every L3 Longitude displays the world on its back. Our in-house R&D team reverse-prints the sapphire with a deep-navy globe and meridian lines, placing the Prime Meridian at your centre – a refined salute to British horology and the spirit of the L3.

CLARITY THROUGH DESIGN

No window dressing – just clear design and mechanical discipline. The L3 uses high-contrast indexing, crisp typography, and an optically correct sapphire crystal to prioritise legibility in all conditions. Regulated in-house to our Chrono10 standard, it keeps its focus where it matters: accurate time, at a glance.

TECH SPEC

Each model in the collection continues to reflect Zero West’s commitment to precision engineering, innovative DualConcentricConstruction™, and distinctive design elements.

- Latitude and Longitude reference Greenwich and the main line of longitude

- Date code references when London was awarded the Prime Meridian, ‘Where time starts’

- White dial, roman numerals and blue hands are a contemporary nod to John Harrisons H4

- Five-axis, aerospace grade 316L stainless steel machining

- Hand-assembled, regulated, and tested in-house to Chrono10 certification

- 42mm diameter, 316L Stainless Steel, matt finish body with polished lugs

- Zero West DualConcentricConstruction™ (DCC™)

- Polished stainless steel back with inset reverse printed sapphire crystal

- Water resistance: 10ATM (100m)

- Main Crown – Matt silver finished sprung, screw-down with triple seal technology

- Front: Deep‑dome, optically corrected sapphire with AR coating

- Rear: Reverse printed globe graphic from the ‘Z Branch’ workshop

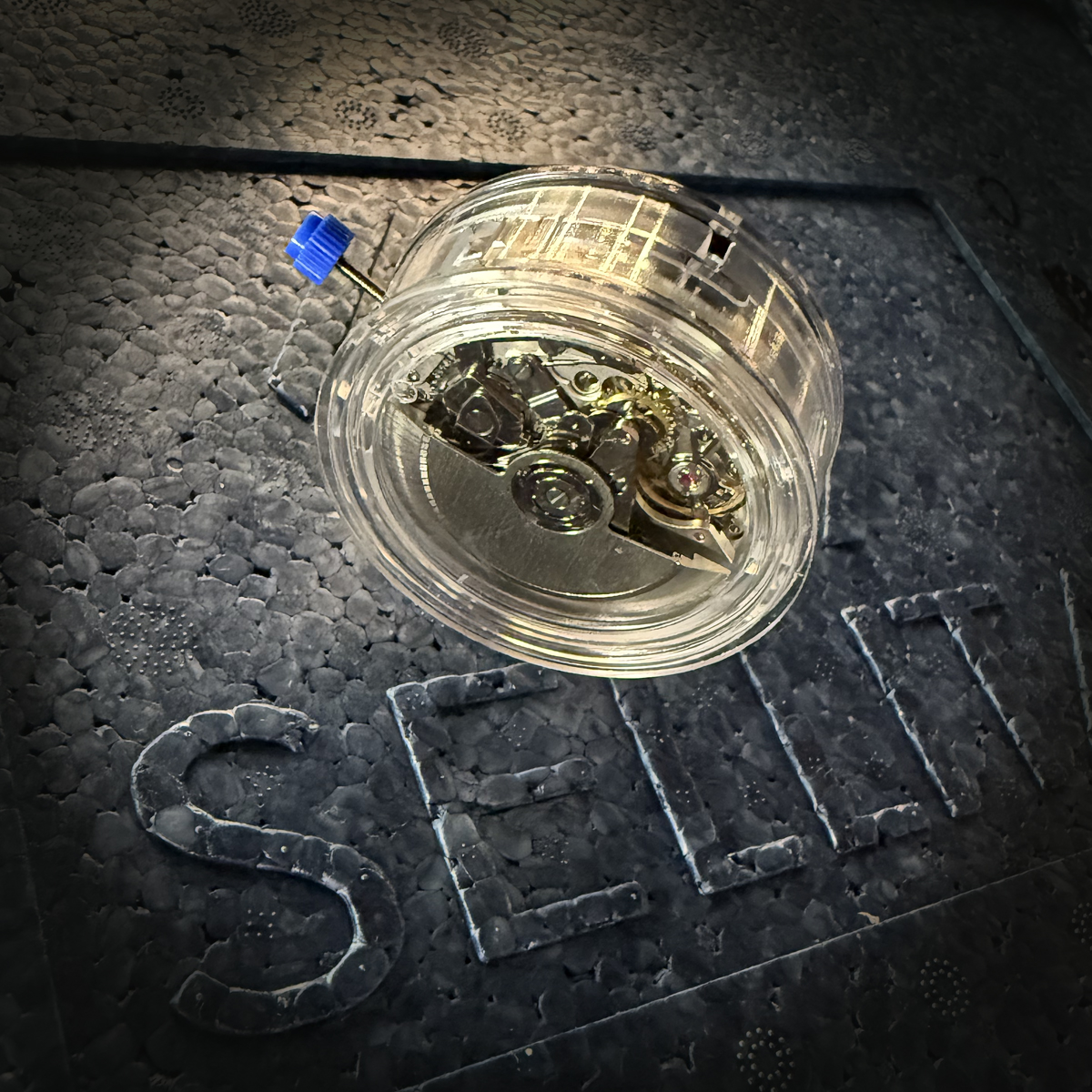

- Sellita SW261-1 ‘Top Premium Grade’

- In house regulated

- 28,800vph

- 31 jewels

- Self-winding ball bearing rotor

- Power reserve ~41 hours

- Antique white with recessed seconds sub dial at 6 O’clock with inset chrome ring

-

Overprinted roman numerals set within train track minute markers; Blue teardrop hour and minute hand with matching chrome seconds hand

- Recessed seconds subdial at 6 o’clock

- 42mm diameter

- 13.2mm thick

- 22mm lug width

- 47mm lug to lug pin spacing

-

Standard rubber 22/20mm. Zero West custom military and aerospace grade cross-linked fluoroelastomer rubber. Matt silver pin buckle

-

Integrated rubber 22/20mm. Zero West custom military and aerospace grade cross-linked fluoroelastomer rubber. Zero West in-house designed deployment buckle

-

Leather padded strap 22/20mm. Handmade with the finest Italian leather and hypoallergenic lined. Matt silver pin buckle. Sizes: Long: 195-235mm / Standard 180-220mm / Short: 170-205mm

-

Leather leather strap 22/20mm. Handmade with the finest Italian leather and hypoallergenic lined. Zero West brushed silver butterfly clasp. Available in standard size 175mm-220mm

-

Metal bracelet 22/20mm. 316 stainless steel, matt silver with polished centre links, designed in-house and uniquely engineered to complement our watch head. Deployment buckle

ZERO WEST – CHRONO10 CERTIFICATION

Chrono10 is Zero West Watches’ proprietary precision testing and certification process, ensuring every L3 timepiece meets the highest standards of accuracy and reliability. Unlike most brands that rely on third-party testing, we perform rigorous in-house evaluations that include multi-temperature testing (8°C, 23°C, and 38°C), six-axis accuracy assessments, and extended stabilization periods before final regulation.

Every Chrono10-certified timepiece leaving our workshop is rigorously tested and regulated to a strict maximum accuracy threshold of −4/+6 seconds per day, with an Average Daily Rate (ADR) target maintained within those limits.

This level of performance is enabled by our commercial partnership with Sellita, who supply us only their Top Grade movements; their statistically controlled batch manufacture and premium materials — including Glucydur balance wheels, Nivachron hairsprings, and quality jewelled anti-shock mounted bearing interfaces — ensure consistent results across our specified real-world temperature range.