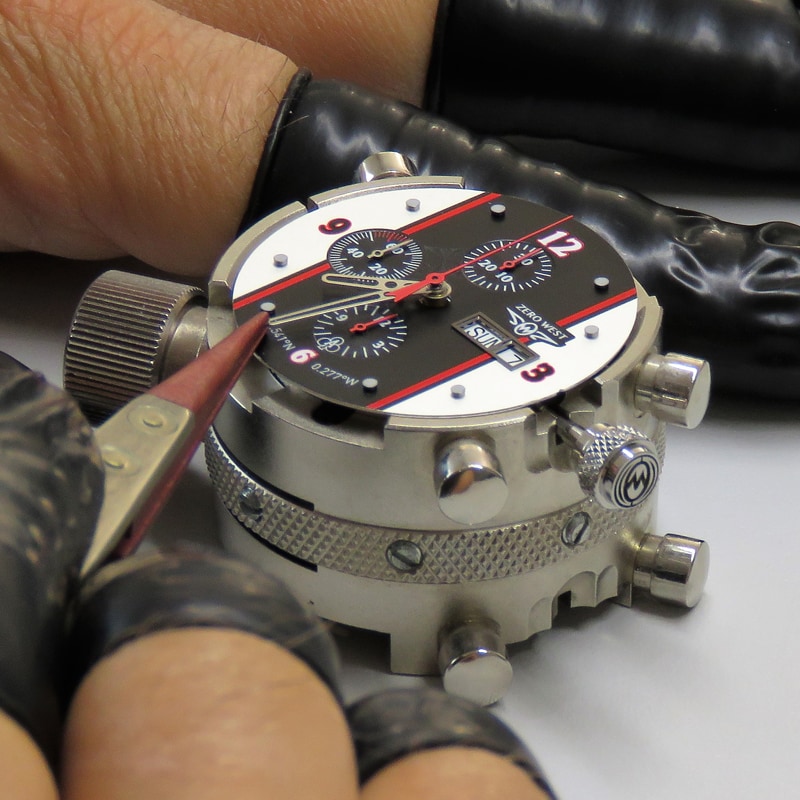

BRAND ENGINEERING

In early 2016 we set out to create a classic British watch brand that celebrated great moments in history through innovative design and engineering. We had a clear vision of what Zero West represented and knew we possessed the collective skills to turn that vision into reality.

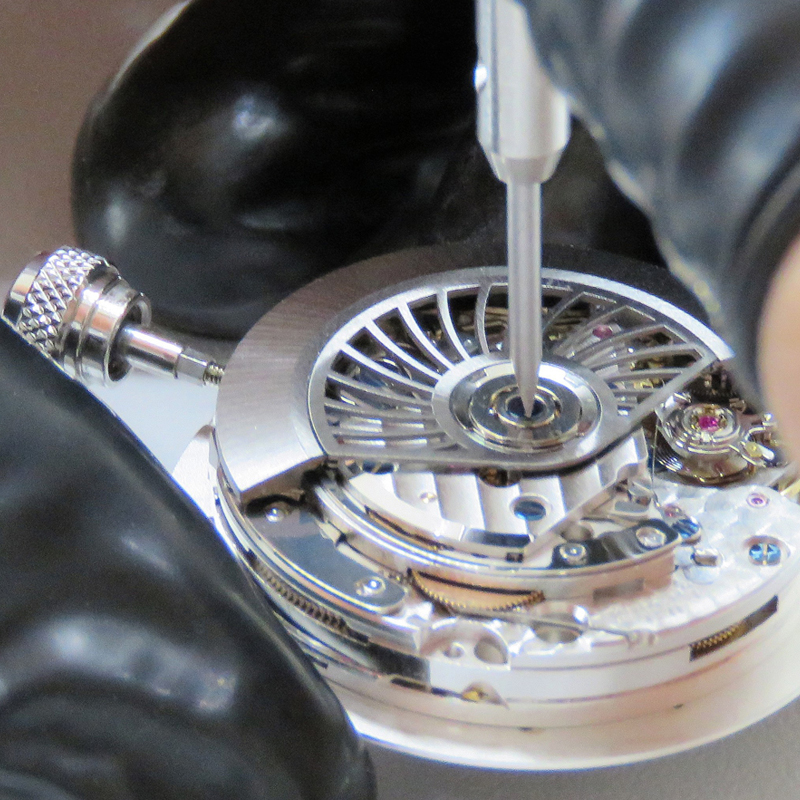

The first step in the design process was to research watch movements and after extensive evaluation, decided to base our designs around the superbly engineered and highly developed Swiss ETA movement range. They are without doubt some of the finest watch movements ever made.