Q-BRANCH

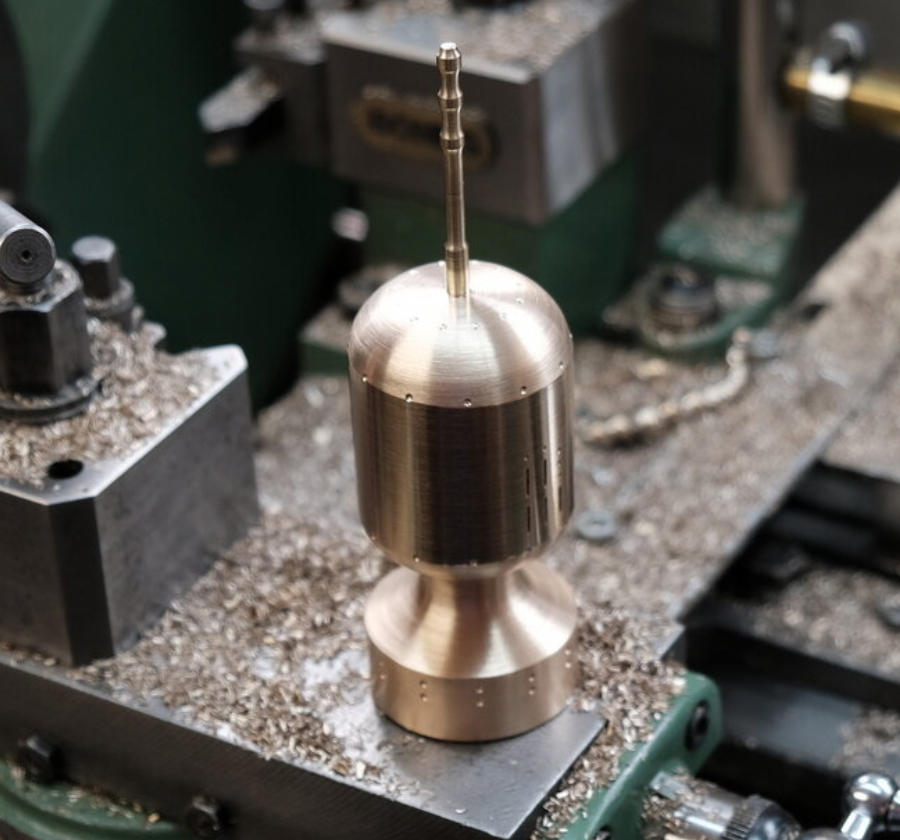

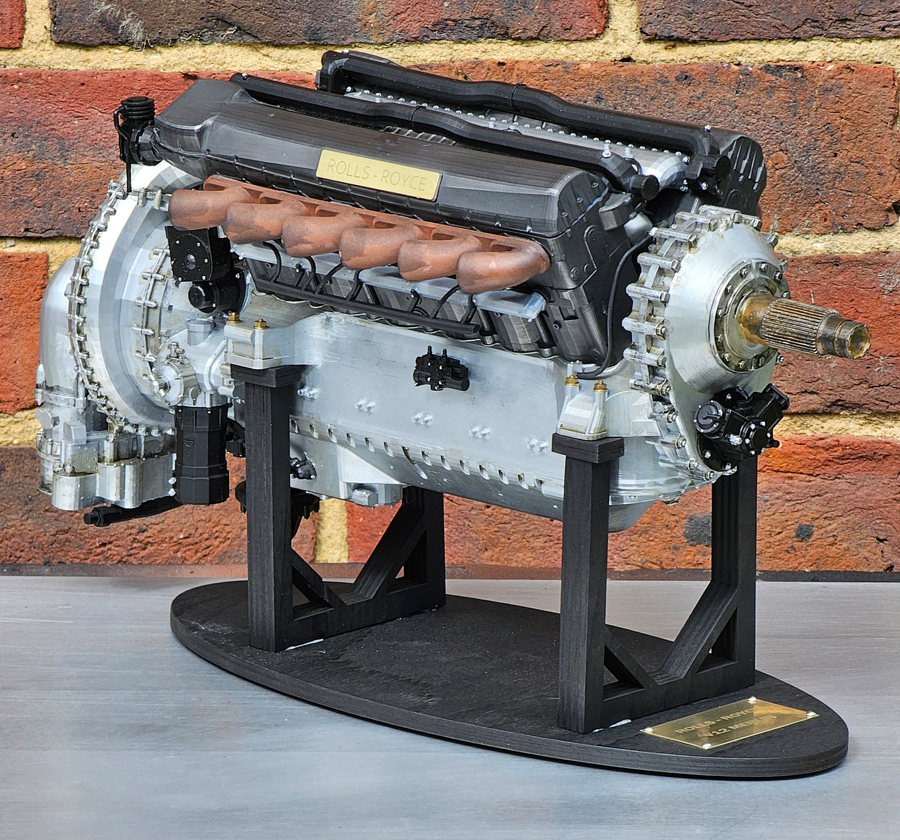

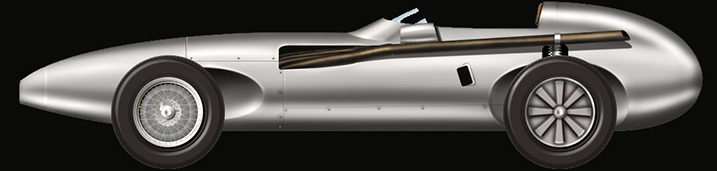

Home of our R&D specialist product wing, Q-Branch is our creative space where the imagination of engineers and designers cross borders between fact and fiction. The result is cool one-off pieces connected by time, horology and the stories that define every watch. And design concepts that make the best of in-house watch manufacture.

In the below interview meet our very own ‘Q’ and you will discover a self-taught engineer, with 20 years experience as a survival equipment fitter in the Royal Air Force.